The printed circuit board is a wonder of conductive tracks, pads, and copper sheets that supports electronic components. However, because of the complexity of PCB design and manufacturing, it bodes well to routinely refresh oneself with the knowledge of PCB terminology and any new additional meanings the terms may have acquired over recent years.

Therefore, listed below is a brief glossary of key PCB design and manufacturing terminology. Some of the words defined have other meanings; however, they may not be listed specifically in this glossary.

- Auto-router — an automatic routing computer program, automatically routes the design of a PC board.

- CAD — Computer Aided Design. Engineers use this system to create a computerized prototype of a design.

- CAE — Computer Aided Engineering.

- CAM — Computer Aided Manufacturing.

- CAM files — Computer Aided Manufacturing files that assist in printed wire manufacturing. Plotter and printer files are sometimes referred to as CAM files by PCB CAM software companies.

- End-to-End Design — a form of CADCAM CAE (computer aided design, manufacturing, and engineering) that software packages utilize as a means of allowing design to run smoothly by integrating both inputs and outputs. A more specific view of End-to-End Design is a reference to the PCB layout interface and electronic schematic.

- Header — mounted on a printed circuit, a part of the connector assembly.

- Lead — on a component, the terminal area.

- Multimeter — can be used to measure resistance, voltage, and current. A test instrument that is portable.

- Rapid Prototype PCB — a prototype PCB, but constructed using rapid prototyping techniques to create a model of a utilizing CAD data. A rapid prototype PCB is typically used when a prototype must be created quickly.

- Temperature Marker — a type of marker or crayon that is used to detect the temperature of a material. The material of the marker is opaque until 413 °F (212 °C) after which the material of the marker takes on a shiny quality and liquefies.

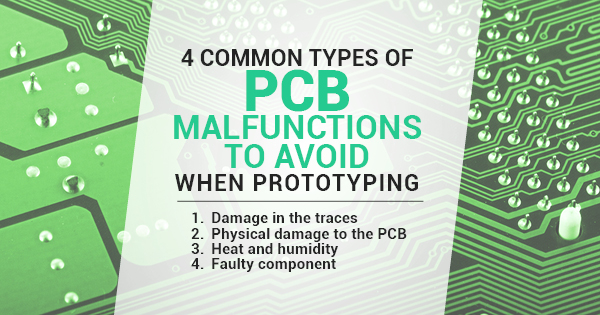

Prototype printed circuit boards are used in a variety of ways, which is why it’s important to perform multiple tests during the production of the printed circuit board for manufacturing purposes. Additionally, it’s important to refresh one’s knowledge of the terminology of PCB design in order to remain efficient and productive in prototype PCB manufacturing.