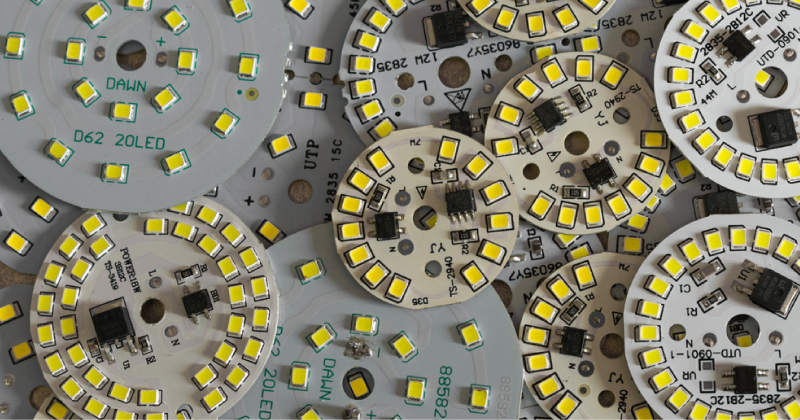

Light Emitting Diodes (LEDs) are very popular these days. You can find LED arrays in a variety of products such as gaming, lighting, home decoration, or even in industrial human machine interfaces, just to name a few.

Most LED products contain a Printed Circuit Board with LEDs and a built-in control logic circuit. Sometimes the control logic circuitry may reside on a separate board that connects to the LED PCB using a particular interface.

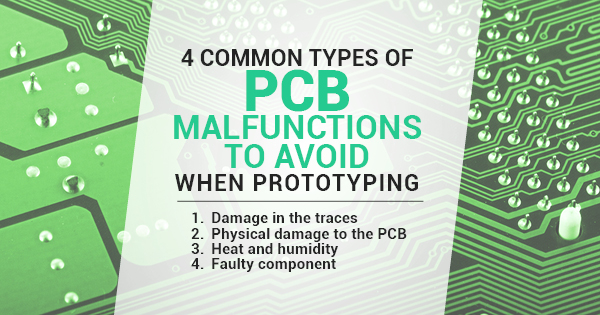

If you need to design a printed circuit board for an LED application, there are some key things to keep in mind.

Power requirements

It is extremely important to calculate how much power all those LEDs will consume. The more LEDs you have, the more power consumption. But other factors, like the efficiency of the LEDs or the brightness at which you operate are variables that affect how much power is required.

Make sure you read the parameters in the LED’s datasheet carefully and if possible, make simulations or test with a smaller number of LEDs in order to calculate the total power consumption and determine the requirements of the power supply.

Heat dissipation

LED circuit boards are well known for heating up. It is necessary to implement techniques that maximize the board’s ability to dissipate the heat. Using copper planes is often recommended.

You can consider using other fabrication technologies, such as metal core PCBs, when the heat dissipation requirements are very high. This can be particularly useful when working with high power lighting systems.

Driver or controller

Depending on what features you want to add to your product, a different kind of controlling element will be required. In many cases a general-purpose microcontroller is all you need. For certain applications, a more specialized IC will be required.

Do you need serial communication? Are you controlling each LED individually, or are you driving all them together? Do you need to create custom patterns (as in gaming or decoration products) or do you want to focus on controlling brightness and maximize efficiency (as in lighting products). All of these are questions you should ask yourself when selecting the appropriate LED driver.

LED itself

Finally, the most important part of any LED printed circuit board: The model of LED to use! Do you need it to be monochromatic, or RGB? Do you need true-white or can you get away with RGB white

The key factors to look are cost, size and reliability. If the PCB real state available is not much, there are small form factors available. Many LED technologies have been introduced like addressable LEDs to facilitate the control and board layout, at a higher cost of the component.

If you need help with a LED project simply call or send us an email. We are here to help.

Phone number: (800) 208-1726

Email: support@pentalogix.com

We can help you design, fabricate and assemble your LED printed circuit boards.