Artificial Intelligence (AI) is catalyzing a significant transformation in the realm of printed circuit board (PCB) design and manufacturing, providing a whole new level of efficiency, accuracy, and innovation across the entire process. This article delves into the diverse applications of AI in PCB design and manufacturing, ranging from optimizing schematic design to refining component selection, parsing datasheets, conducting circuit calculations, managing PCB layout, and beyond. Through the utilization of advanced algorithms and machine learning methodologies, AI is redefining conventional approaches and heralding a fresh chapter in electronic design engineering.

PCB Design Applications

Artificial Intelligence is changing the way printed circuit boards are designed, offering innovative solutions to enhance efficiency, accuracy, and creativity in the design process. From schematic design to component selection, datasheet parsing, and circuit calculations, AI technologies are reshaping traditional design practices.

Companies such as Altium, Cadence, and Mentor Graphics are integrating AI algorithms into their software suites to streamline workflows, improve design accuracy, and offer intelligent design recommendations to users. These advancements are empowering designers to achieve higher levels of productivity and innovation in PCB design.

AI in Schematic Design

AI is rapidly taking over several design processes in the printed circuit board space. Due to its nature, schematic design is adapting fairly well to new artificial intelligence technologies. PCB layout is still a more challenging aspect for AI algorithms, but certain tasks are being optimized with the help of generative AI.

Component Selection

During schematic design, AI expedites component selection by analyzing extensive databases of specifications, historical data, and performance metrics, providing tailored recommendations aligned with project requirements and constraints. Leveraging machine learning, AI systems identify components based on factors like electrical characteristics, cost, availability, and compatibility, streamlining the process and minimizing errors. By considering design preferences and rules, AI suggests components meeting specific criteria, ensuring suitability for the application.

Datasheet data extraction

AI can save significant time in the schematic design process by automating the extraction and analysis of information from datasheets. Rather than manually scrolling through datasheets for component specifications, AI algorithms can quickly parse through vast databases of datasheets, extracting relevant information such as pin configurations, electrical characteristics, and application notes. By automating this process, designers can quickly access the information they need to make informed decisions about component selection and circuit configuration, saving valuable time and accelerating the design process.

Circuit Calculations

Utilizing machine learning algorithms, artificial intelligence systems analyze design parameters, component specifications, and design constraints to perform calculations related to component values, voltage drops, current requirements, impedance matching, and signal integrity. This automation minimizes errors and ensures efficient compliance with design constraints. Moreover, AI provides intelligent suggestions and alternatives based on calculated results, empowering designers to make informed decisions and optimize PCB layout performance effectively.

AI in PCB Layout

Generative Component Placement

Generative AI is transforming PCB component placement by automating and optimizing layouts based on specific design criteria and constraints. Leveraging machine learning algorithms, it analyzes vast datasets of PCB layouts and component specifications to predict how different placements will affect performance metrics such as signal integrity and thermal management. By exploring a broader design space than manual methods allow, generative AI enables more innovative and optimized solutions. Additionally, it can balance multiple objectives simultaneously, ensuring that components are positioned to minimize signal interference while effectively managing heat dissipation. Ultimately, generative AI accelerates design workflows, reduces design time, and enhances the performance and reliability of electronic systems.

Automated Routing

AI revolutionizes printed circuit board routing by automating and optimizing the complex process of tracing electrical connections between components. Through advanced algorithms, AI systems analyze design rules, component placements, and routing constraints to generate efficient routing solutions. By considering factors such as signal integrity, electromagnetic interference, and manufacturing constraints, AI ensures high-quality designs while reducing design time.

PCB Manufacturing Applications

AI revolutionizes printed circuit board routing by automating and optimizing the complex process of tracing electrical connections between components. Through advanced algorithms, AI systems analyze design rules, component placements, and routing constraints to generate efficient routing solutions. By considering factors such as signal integrity, electromagnetic interference, and manufacturing constraints, AI ensures high-quality designs while reducing design time.

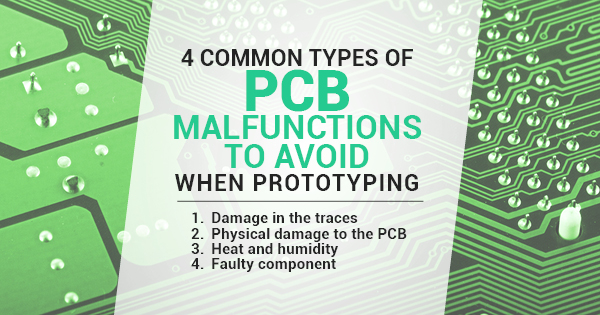

Quality Assurance

AI can improve the quality assurance process by analyzing images of printed circuit boards to detect defects such as missing or misaligned components, soldering defects, and hairline cracks. Machine learning algorithms trained on large datasets can accurately identify defects and classify them according to severity, enabling manufacturers to quickly identify and rectify issues before they impact product quality.

Predictive Maintenance

AI can improve the quality assurance process by analyzing images of printed circuit boards to detect defects such as missing or misaligned components, soldering defects, and hairline cracks. Machine learning algorithms trained on large datasets can accurately identify defects and classify them according to severity, enabling manufacturers to quickly identify and rectify issues before they impact product quality.

Process Optimization

AI can optimize various manufacturing processes involved in PCB manufacturing, such as etching, drilling, and soldering. By analyzing process parameters and performance data in real-time, AI algorithms can identify opportunities for optimization, improve yield rates, and reduce energy consumption.

PCB Manufacturing Applications

AI is not just a trending word or a futuristic sci-fi topic. It is a reality, and is part of the present. As we continue to embrace AI-driven advancements, the future of PCB design and manufacturing looks brighter than ever, with enhanced productivity, reliability, and quality, paving the way for further innovation and growth in the industry.